Technical Data Guide

- Home

- Technical specs and info

ULTRAFLO® IS A CALCIUM SULPHATE, HEMIHYDRATE, PUMP APPLIED LIQUID FLOOR SCREED.

Compliance

Ultraflo® has been designed to comply with BS EN 13813:2002, screed material and floor screeds, screed material – properties and requirements.

Application

Subfloor levelling.

For use with underfloor heating systems.

Unbonded, bonded and floating floor constructions.

Suitable for both residential and commercial floors.

Shrinkage

Ultraflo® has minimal drying shrinkage. Movement joints need only be considered where the floor exceeds 1000m2, or where the floor becomes elongated and an aspect ratio of 1:6 is exceeded. Movement joints should also be considered across doorways. When used with under-floor heating systems, movement joints should be considered between different heating zones or when the floor exceeds 300m2.

Compaction

The flowing characteristics of Ultraflo® means it is self- compacting thus voids and poor compaction are virtually eliminated.

Durability

As with virtually all screeds, Ultraflo® is not a wearing surface and it therefore requires a suitable floor covering. Ultraflo® can be used with all standard floor coverings i.e. tiles, wood, carpet, vinyl.

Wet Areas

Ultraflo® is not suitable for areas which are in regular contact with water e.g. communal showers, wet rooms, exterior yards or similar.

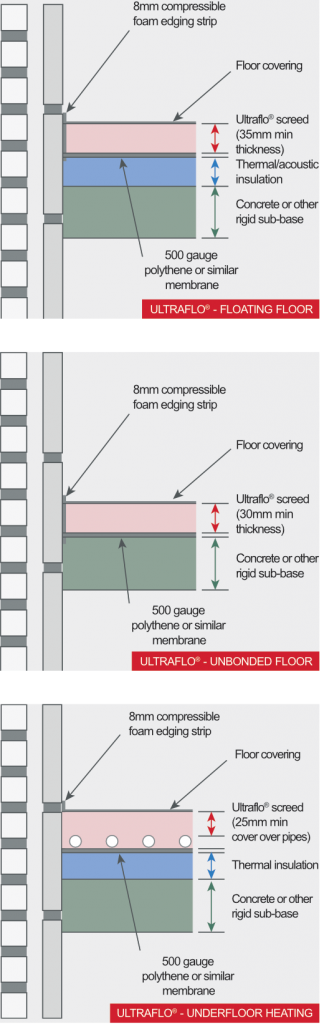

Minimal Application Thickness

Bonded | 25 mm |

Unbonded | 30mm |

Floating (Commercial) | 40mm |

Floating (Domestic) | 35mm |

Under-floor Heating | 25mm (Min to Cover Pipes) |

NOTE: Any deviations in the levels and surface regularity of the base slab should be taken into consideration when determining the thickness of screed, to ensure the minimum thickness can be achieved.

Key Features

- Very low shrinkage, does not curl.

- Movement joint requirements greatly reduced.

- Can be walked on 24 hours after application.

- Increased productivity – 2000m2 per day can be easily achieved.

- Significantly reduced thickness when compared to traditional sand:cement screeds.

- Reduced depth means reduced weight and drying times.

- Can be force dried.

- Under-floor heating systems, can be turned on after 7 days.

- Increases efficiency of under-floor heating system.

- Quicker heat response time with underfloor heating.

- Environmentally friendly.

Technical Properties

Flow (DIN 1060 Test) | 230-250 mm |

Plasitc Density | 2060-2130 kg/m3 |

Dry Density | 1950-2050 kg/m3 |

Flexural Strength | >4 N/mm2 |

Fire Rating | Non-combustible |

Thermal Expansion Co-Efficient | 0.01mm/mk |

Thermal Conductivity | 1.66-1.88 W/mk |

Drying Shrinkage | Less than 0.02% |

Drying Time* *40mm depth, ambient 20ºC and 65% relative humidity | 1 day/mm |

Installation

Ultraflo® must only be installed by approved contractors. The building should be weather tight, i.e. roof on, doors and windows installed and any openings made weather tight prior to installation. It is recommended that Ultraflo® is laid on 500 gauge polythene, with 8-10 mm compressible edging strip around the perimeter of the room. All joints should be taped to create a tanking system.

The finished level of the screed is set using laser levels and tripod indicators throughout the room. Ultraflo® is delivered to site ready mixed and will have been tested prior to discharge for flow characteristics. It is pumped into place and in practice takes approximately 30 minutes to pump 6m3. The screed is then dappled to create a smooth, level surface.

Drying

Immediately after application and until the screed has hardened, protect the surface of the screed from water ingress, direct sunlight and severe draughts. After 24 hours, windows should be opened to allow drying. Dehumidifiers can be turned on to force dry the screed after 7 days. Ultraflo® can be lightly trafficked after 24 hours, depending on drying conditions. Ultraflo® will dry at 1mm/day up to 40mm thickness (20°C, 65% relative humidity). This increases for screeds of thicker depths and in poor drying conditions. The underfloor heating systems can be commissioned after 7 days to force dry the floor. The under-floor heating system should be increased from ambient to normal working temperature in 5°C steps per day.

Application of Floor Covering

The screed must be sufficiently dry before any floor coverings are applied. For permeable floors such as carpets, moisture content less than 1% is required. For impermeable floor coverings such as vinyl or tiles, moisture content less than 0.5% is required. When applying cement-based adhesives, the screed must be primed with an acrylic or epoxy based primer.

*All thickness as per BS 8204-7